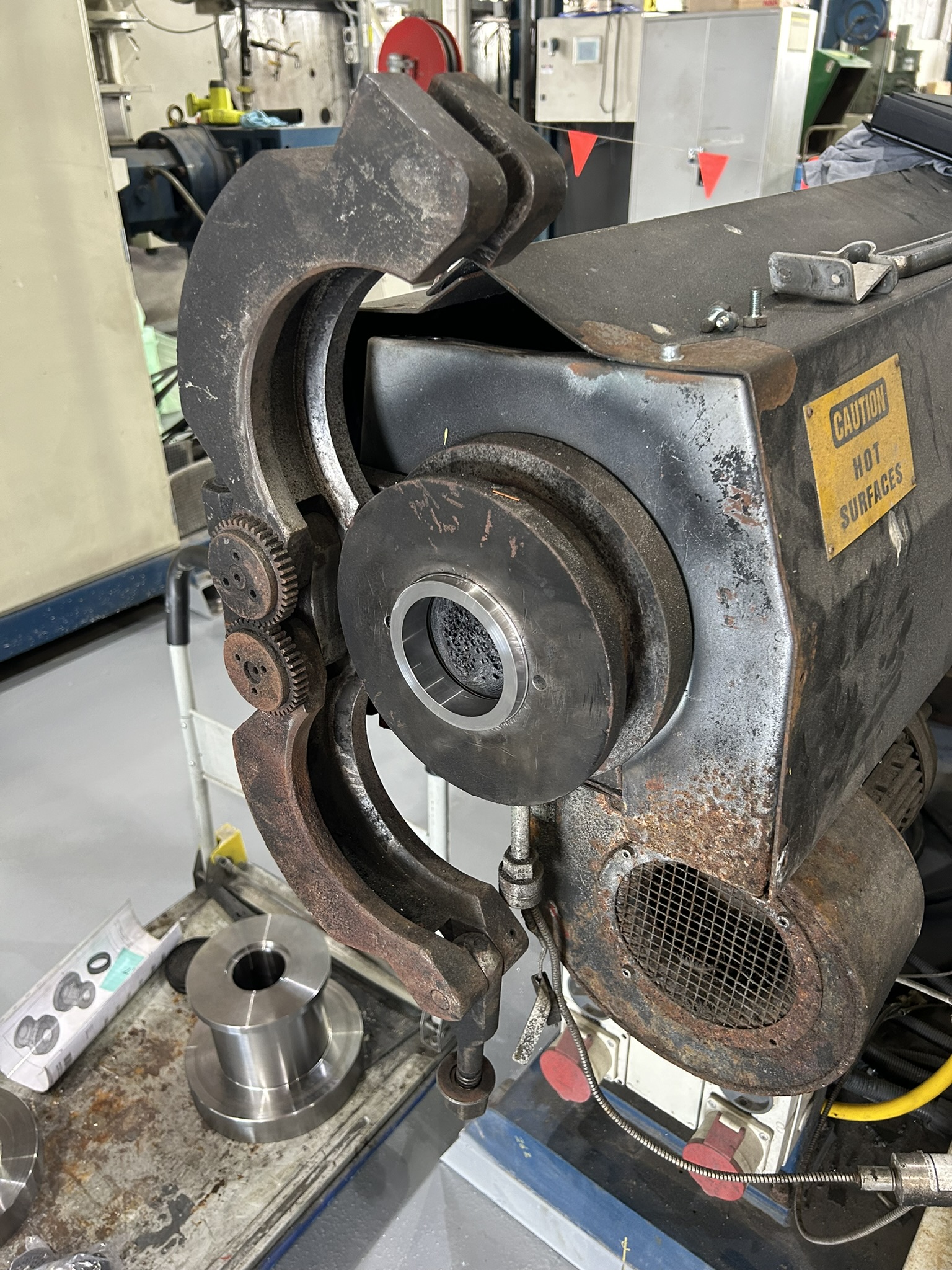

Incompatibility between the newly acquired plastic extruder and existing extrusion dies.

Different brands of machinery not designed to work together.

The need to ensure smooth, uninterrupted production and maintain high-quality standards.

Our team of experienced engineers developed a comprehensive solution to overcome the challenges posed by the incompatible machinery.

Steps Taken:

Thorough Analysis: Conducted an in-depth analysis of both the plastic extruder and the extrusion dies.

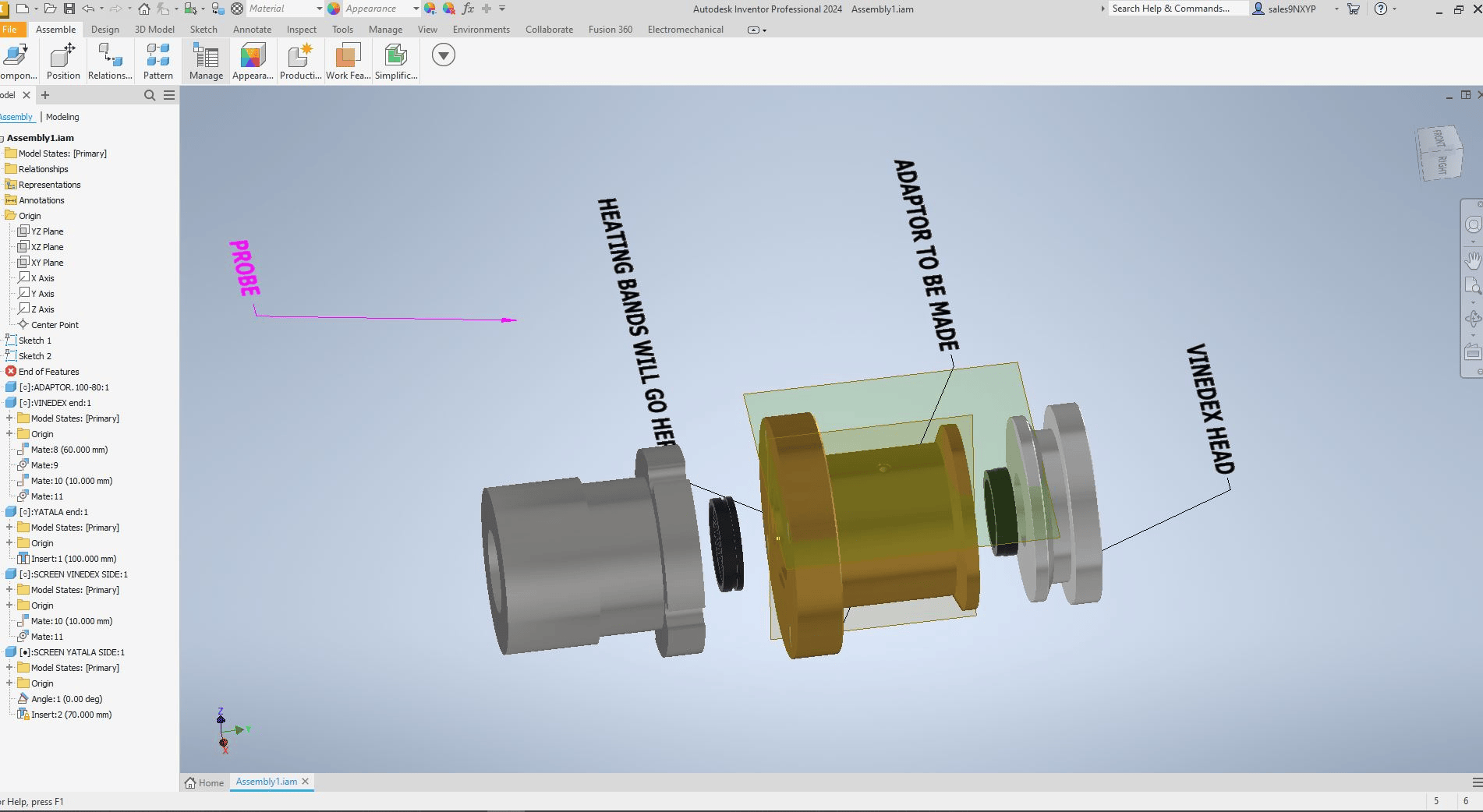

Custom Prototype Development: Designed and developed a custom prototype to bridge the gap between the incompatible components.

Precise Modifications: Modified the extruder to align with Vinidex’s specific die requirements, employing advanced design tools and techniques.

Rigorous Testing: Commissioned and rigorously tested the solution to ensure flawless operation between the extruder and dies.

Incompatibility between the newly acquired plastic extruder and existing extrusion dies.

Different brands of machinery not designed to work together.

The need to ensure smooth, uninterrupted production and maintain high-quality standards.

Our team of experienced engineers developed a comprehensive solution to overcome the challenges posed by the incompatible machinery.

Steps Taken:

Thorough Analysis: Conducted an in-depth analysis of both the plastic extruder and the extrusion dies.

Custom Prototype Development: Designed and developed a custom prototype to bridge the gap between the incompatible components.

Precise Modifications: Modified the extruder to align with Vinidex’s specific die requirements, employing advanced design tools and techniques.

Rigorous Testing: Commissioned and rigorously tested the solution to ensure flawless operation between the extruder and dies.

The project resulted in a complete end-to-end solution for Vinidex Solutions, achieving seamless integration of the plastic extruder with the existing extrusion dies.

This case study underscores our commitment to customer satisfaction and our expertise in solving complex engineering challenges.

Machining

At Dalzell and Bagley Engineering, we provide work to the highest standards in both machining and project management. Our schedule drives our life and gives you confidence that your work will be done at the agreed time and to the agreed tolerances.