Frequent Breakdowns: Disrupting racing events and leading to significant downtime for repairs.

Cost Implications: Repairs driving up maintenance costs, impacting the overall affordability of racing.

Safety Concerns: Compromised durability raised safety concerns.

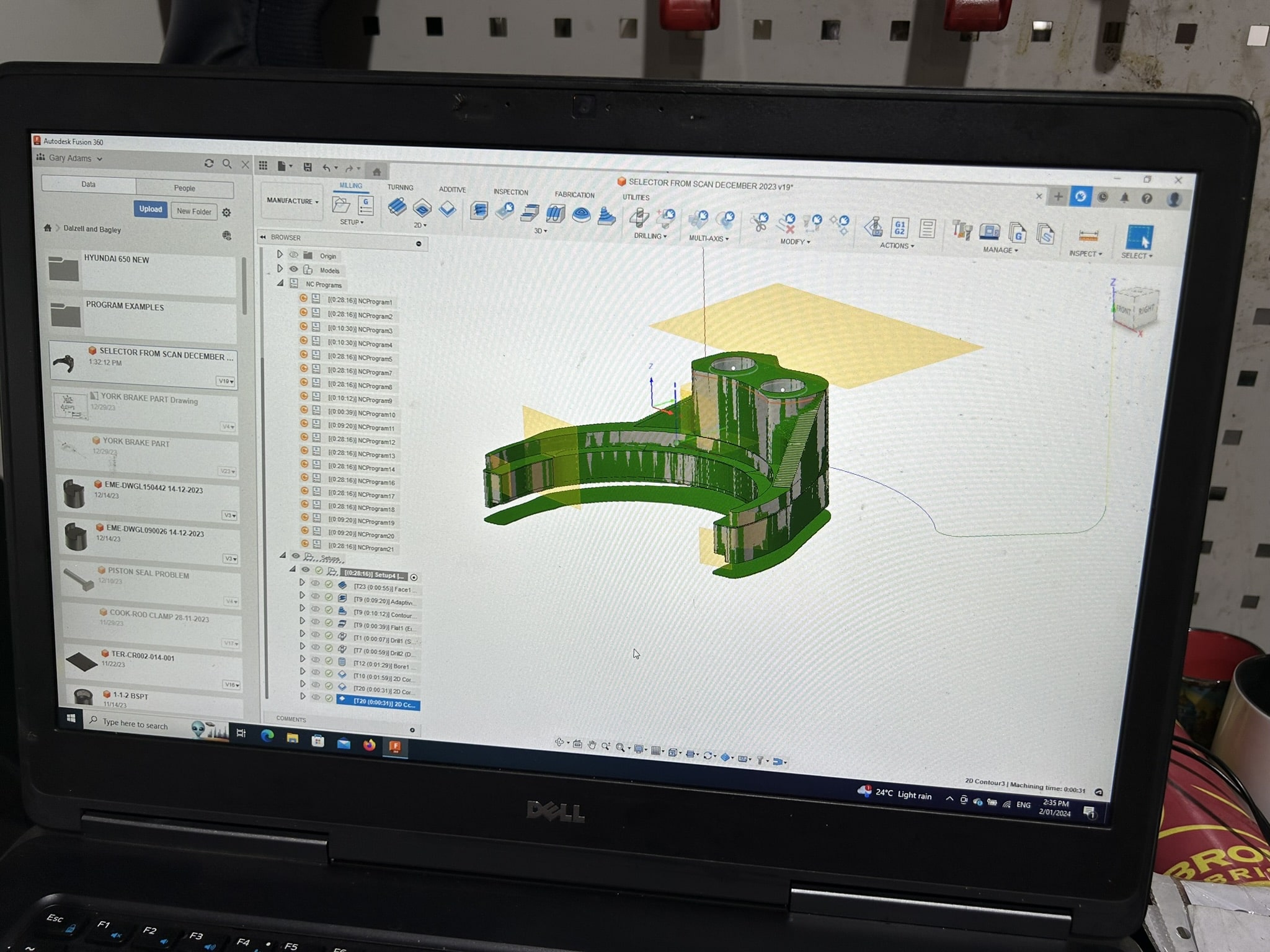

Dalzell and Bagley Engineering took a comprehensive approach to address CERA’s challenges. The solution involved reverse engineering the gearbox components, specifically the selector and knuckle, and utilising advanced CAD and CAM software for precise modelling and manufacturing.

Reverse Engineering: Dalzell and Bagley Engineering identify weaknesses and failure points.

CAD and CAM Modelling: Leveraging state-of-the-art CAD and CAM software, Dalzell and Bagley Engineering created a computer model that incorporated improvements to enhance durability. The digital modelling allowed for precise specifications, ensuring the new components would meet the highest standards.

Material and Design Improvements: The solution included manufacturing the redesigned selector and knuckle from a single billet of steel. This not only improved the overall strength but also eliminated potential weak points associated with assembly. Specific sections were strategically thickened to reinforce vulnerable areas, preventing further breakage under the intense conditions of racing.

Frequent Breakdowns: Disrupting racing events and leading to significant downtime for repairs.

Cost Implications: Repairs driving up maintenance costs, impacting the overall affordability of racing.

Safety Concerns: Compromised durability raised safety concerns.

Dalzell and Bagley Engineering took a comprehensive approach to address CERA’s challenges. The solution involved reverse engineering the gearbox components, specifically the selector and knuckle, and utilising advanced CAD and CAM software for precise modelling and manufacturing.

Reverse Engineering: Dalzell and Bagley Engineering identify weaknesses and failure points.

CAD and CAM Modelling: Leveraging state-of-the-art CAD and CAM software, Dalzell and Bagley Engineering created a computer model that incorporated improvements to enhance durability. The digital modelling allowed for precise specifications, ensuring the new components would meet the highest standards.

Material and Design Improvements: The solution included manufacturing the redesigned selector and knuckle from a single billet of steel. This not only improved the overall strength but also eliminated potential weak points associated with assembly. Specific sections were strategically thickened to reinforce vulnerable areas, preventing further breakage under the intense conditions of racing.

Dalzell and Bagley’s collaboration led to significant improvements in gearbox durability, reducing breakdowns and costs. The innovative approach showcased their ability to transform challenges into continuous improvements in motorsport engineering

Machining

At Dalzell and Bagley Engineering, we provide work to the highest standards in both machining and project management. Our schedule drives our life and gives you confidence that your work will be done at the agreed time and to the agreed tolerances.