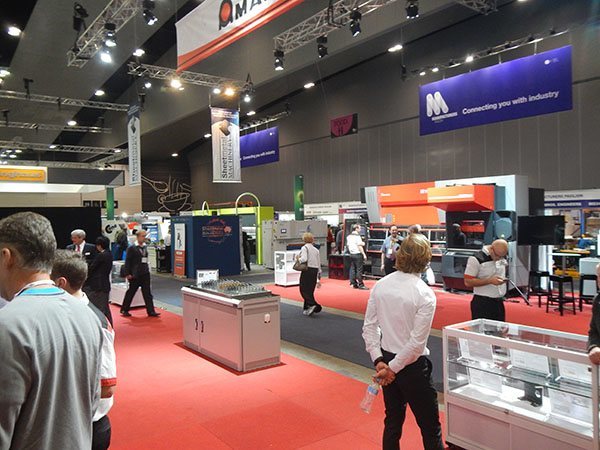

National Manufacturing Week 2015 was held at the Melbourne Convention and Exhibition Centre in the last week of May. It is Australia’s largest showcase of manufacturing innovation, information & inspiration, with exhibitors from across the globe. We took the opportunity to see what the latest trends and products are by attending two days of the exhibition.

National Manufacturing Week 2015 was held at the Melbourne Convention and Exhibition Centre in the last week of May. It is Australia’s largest showcase of manufacturing innovation, information & inspiration, with exhibitors from across the globe. We took the opportunity to see what the latest trends and products are by attending two days of the exhibition.

More than 220 exhibitors ranged from Software Suppliers, CNC Machinery dealers, 3D Printer sales and International Trading Companies to name just a few.

One particular industry seems to have been a key theme for NMW this year, and that is 3D Printing. More 3D Printer manufacturers were on display than ever before. With 3D Printers producing parts from Resin, Plastic and Titanium, the range of products that could be manufactured seem limitless.

This early technology is still coming to grips with a few aspects of manufacturing, so for now traditional methods still prove more viable. For example, the cycle time taken to produce a part in most instances, is far longer than traditional machining methods. Also, quite often the materials used in the printing are more expensive than pre-manufactured composites that are readily available from local suppliers. But these are still early days for 3D Printing, and with the growth in this technology developing at the rate it is, the question must be asked, is this the future of manufacturing in Australia?

This early technology is still coming to grips with a few aspects of manufacturing, so for now traditional methods still prove more viable. For example, the cycle time taken to produce a part in most instances, is far longer than traditional machining methods. Also, quite often the materials used in the printing are more expensive than pre-manufactured composites that are readily available from local suppliers. But these are still early days for 3D Printing, and with the growth in this technology developing at the rate it is, the question must be asked, is this the future of manufacturing in Australia?

Another industry that was quite dominant at this years NMW, was foreign trading companies that focused on a business model of brokering machining, casting and forging, or fabrication work to foreign manufacturers on behalf of Australian companies. These trading companies will source independent machining and fabrication services overseas, and send the parts back to Australia.

These companies act as a middleman, arranging the manufacturing for Australian companies, using whichever foreign supplier is available at the time. While there are perks to this model and cost is one of them; there are some severe pitfalls to be wary of, the quality of manufacturing is chief among them. As well as the consistency of parts that comes from working with the same manufacturer.

These companies act as a middleman, arranging the manufacturing for Australian companies, using whichever foreign supplier is available at the time. While there are perks to this model and cost is one of them; there are some severe pitfalls to be wary of, the quality of manufacturing is chief among them. As well as the consistency of parts that comes from working with the same manufacturer.

There can be no doubt this is a threat to manufacturing in Australia, however it needs to be seen as a challenge and an opportunity to improve the efficiency and capabilities of Australian Manufacturers so that they can remain competitive in the future.

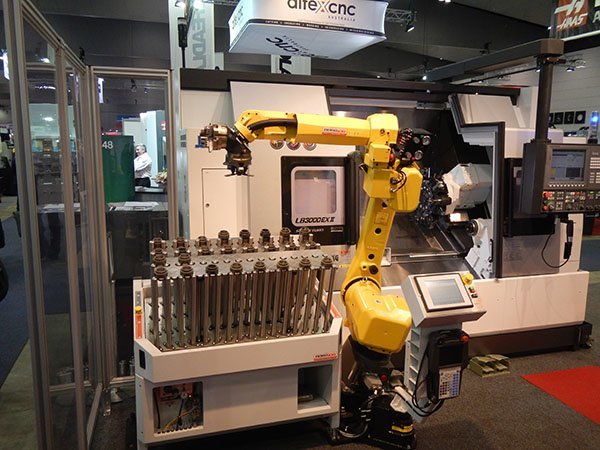

There were also some truly spectacular CNC Machines on show from Okuma and DMG Mori. They showcased their technology by machining a variety of parts including a large bevel gear from solid billet. Also on display from these Machinery Dealers, were robotic part loaders.

Teaming up with RoboJob, Okuma presented a 5-Axis CNC Lathe set up with a Robotic Arm Loader. This machine was manufacturing small pins, with the robot loading and unloading each part from the Lathe for machining.

Teaming up with RoboJob, Okuma presented a 5-Axis CNC Lathe set up with a Robotic Arm Loader. This machine was manufacturing small pins, with the robot loading and unloading each part from the Lathe for machining.

Renishaw exhibited the latest Coordinate Measuring Machines, with their Equator 300 model taking centre stage. This machine enables an operator to load a part into the machine, for it to accurately measure and QA the item for release. It offers extremely accurate measurement of the part, recording of the data and all faster than any operator could achieve with traditional measuring equipment.

NMW 2015 provided us with another chance to keep up to date with the current manufacturing climate, and the newest available technology. As with every other year, we leave Melbourne with new ideas, renewed confidence and a fresh approach to the latest technology. Next year NMW will be in Sydney from 11-13 May. If you get the chance, I recommend you take a look, with such a variety of manufacturing industries on show there is something there for everyone.

NMW 2015 provided us with another chance to keep up to date with the current manufacturing climate, and the newest available technology. As with every other year, we leave Melbourne with new ideas, renewed confidence and a fresh approach to the latest technology. Next year NMW will be in Sydney from 11-13 May. If you get the chance, I recommend you take a look, with such a variety of manufacturing industries on show there is something there for everyone.